NOTE: Perform this operation at your own risk! This requires very strong skills in

mechancial and electroincs repair.

Before removing the instrumet cluster from the vehicle, make sure the ignition

is switch off and the key remove, or you may generate an SRS error that may

require visiting an authorized service center to repair.

You will need a

tool to remove the cluster from the dash.

Mercedes-Benz makes an official tool, and some people will claim that

you must use the OEM tool or risk damaging your vehicle. The reality is, once you see what you are doing,

you will understand why it’s not really that critical. I use a stiff piece of wire (cut from a

coathanger), bent as shown. The working

end is the small end and it’s about 3/8 of an inch long. It’s about 6 inches in length, and the other

end is just over an inch, and is the handle.

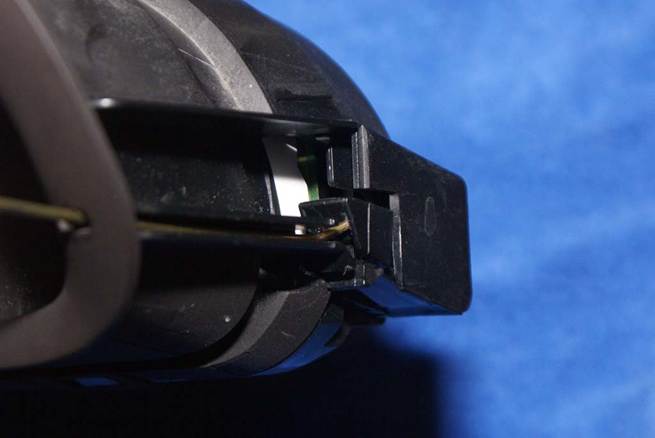

Insert the tool into the slot in

the cluster until to contacts the locking mechanism.

The locking mechanism grips the

dash on the bottom of the cluster. Just

rotate the tool slightly and continue pressing in to move the release upward

and thus allow the cluster be release form the dash. You have to do this on both sides, so you

might want to make two tools and use them simultaneously (though you can use

just one tool and release one side at a time).

Once the cluster locks are

released, remove the unit from them dash and disconnect the electrical connector. It has a locking lever that must be lifted up

and then the connector can be unplugged and the cluster removed from the

vehicle.

To disassemble the cluster, there

are five plastic tabs, three on to and two on the bottom,

that must be released. You can use

your fingers, a screwdriver, or a plastic tool to gently release the tabs and

pull the cluster apart.

Once

the tabs are released, remove the clear lens part of the cluster assembly.

Now you need to remove the bezel

that covers the LCD display. Pry outward

on it as shown on the top.

Once the bezel is removed, you will

see that the LCD panel is held in place by the plastic clips on the white

surround.

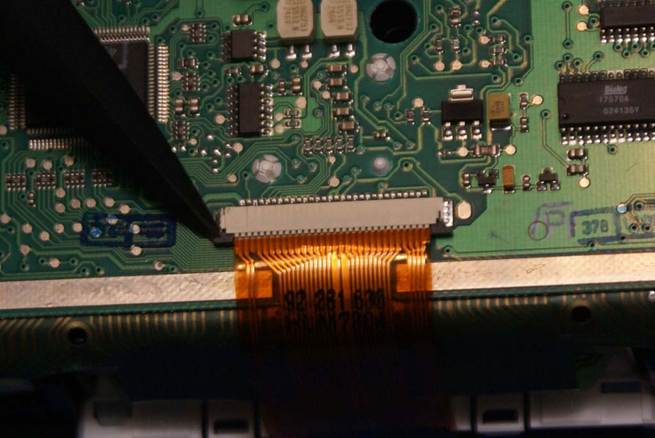

Before removing the LCD panel, you

need to disconnect its electrical connection.

Turn the cluster over to the back.

Press on the outer edges of the brown locking bar as shown to move it

away from the connector.

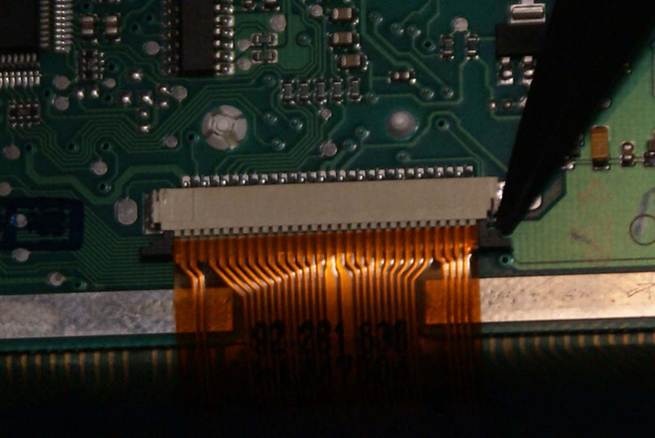

Once the brown locking bar has been

release, the ribbon cable can be pulled out of the connector.

With the ribbon cable disconnected,

you can remove the LCD panel. Pry

between the white plastic clips at the bottom of the panel to release it.

Once the LCD panel has been

removed, you now need to remove diffuser and the lens.

Pry on the plastic clip at the top

of these pieces to release them.

Shown in order of assembly (bottom

to top), you have the diffuser, the lens and the LCD panel:

Next, the plastic holder for he LCD

panel needs to be removed.

Use a T10 Torx

driver to remove the two screws holding the plastic holder in place.

After the two screws are removed,

the plastic LCD display holder can be removed from the cluster:

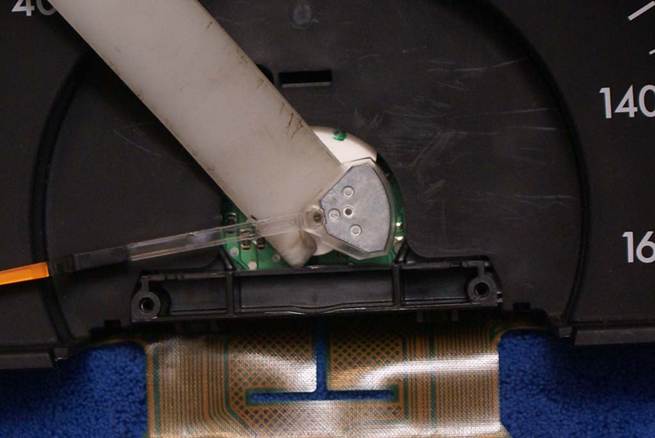

Next, remove the Mylar circuit

board that contains the LED’s away from the speedometer face. It is held in place by snapping onto two plastic

studs. Pry gently and it will come

loose.

Fold the Mylar circuit board down

out of the wat to expose the speedometer cover.

Remove the speedometer cover by

prying on the two plastic tabs on its bottom edge.

The speedometer cover shown removed

from the cluster:

You can now see the speedometer

needle attached to the servo.

Remove the needle by prying gently

from behind.

Be sure to pry against the servo so

that it does not come apart.

Turn the cluster over and now you

can remove the circuit board by release the two plastic clips holding it on

either side.

Fold the circuit board down to

reveal the speedometer servo.

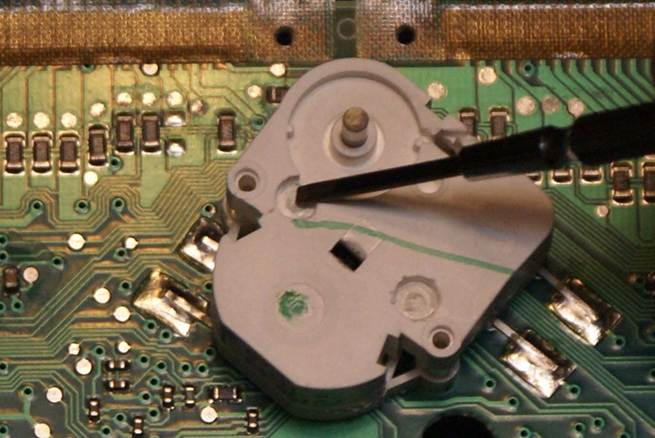

To remove the cover on the servo,

you will need to first shave the melted plastic heads from the two suds as shown.

A small flat head “micro”

screwdriver works well for this. Just

scrape the melted plastic away.

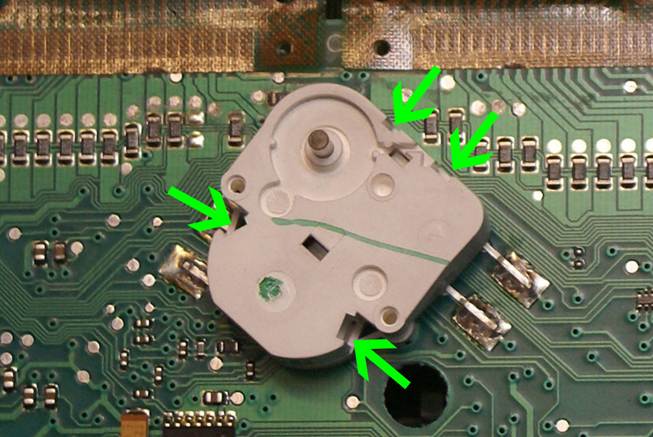

Once the studs are broken loose,

you will need to pry very gently on the four retaining clips to release

them. Generally, you can pry on them one

at a time with a small screwdriver while lifting on the house and it will come

apart.

Gently remove the servo cover from

the circuit board. The main gear may

come off with the cover.

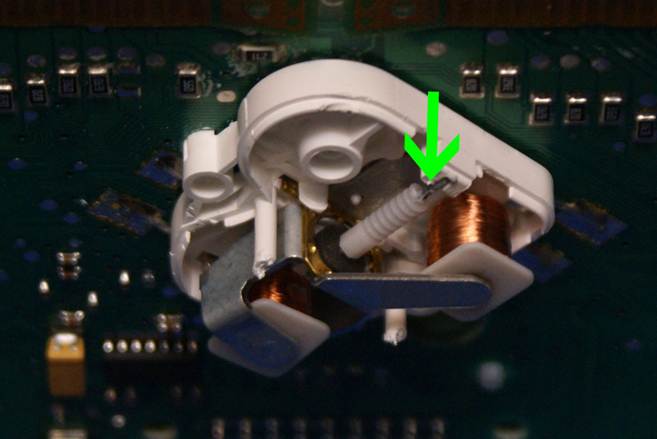

Make sure that the servo worm gear

is in place. Its shaft sits loosely in a

slot in the plastic housing as shown.

Remove the main drive gear from the

servo cover and place it into the servo housing. There is a small stud on the bottom of it

that is a stop for the needle sweep.

Place it as shown, which is just clockwise forward of

the plastic stop in the servo housing.

Now, snap the cover back onto the

servo. Fold the circuit board back over

the cluster housing and snap it into place.

Reinstall the cluster in the vehicle and connect the electrical

connection. You will need to switch on

the ignition to allow the system to self-calibrate BEFORE installing the speedometer

needle. If the speedometer servo “clicks”,

this means that the main gear is not properly installed. Immediately turn the ignition off, and remove

the cluster and reset the main gear as shown above. If the servo does not click, then you can now

install the speedometer needle, being careful to place it in the 0mph position,

without turning the servo. Switch the

ignition off and back on one more time to verify that the speedometer needle is

in the proper position.

Now, switch the ignition off,

remove the key (again, DO NOT disconnect the cluster unless the ignition is off

or it WILL create an SRS error). Remove

the cluster and reassemble it following the above steps backward:

Snap the speedometer cover back in

place.

Place the Mylar circuit board back

in place on the studs on the speedometer cover.

Place the LCD display holder back

in place and attach it with its two screws.

Insert the diffuser, then the lens,

into the LCD display holder.

Place the LCD panel in the holder,

top edge first. Gently press it toward

its top edge to allow it to snap into the clips on the bottom edge.

Insert the LCD’s ribbon cable into

its connector on the back of the cluster, then snap

the brown retaining clip back into place.

Place the bezel on the LCD panel, bottom

edge first then snap the top edge into its clips.

Place the cluster into the bottom

half of its housing, then snap the top “lens” half onto it, making sure all

five plastic clips lineup properly and snap into place.

Reinstall the cluster in the vehicle

by connecting the electrical cable and then pressing it firmly back into the

dash opening until the retaining snap into place and it is held securely.